Most problems go undetected until there is an operating failure. Usually the failure causes extensive damage and creates some interruption of normal operation schedules.

Thermographic Inspections can catch potential problems before they are ever realized. If done periodically, these predictive thermal inspections can save maintenance cost and prevent unexpected downtime.

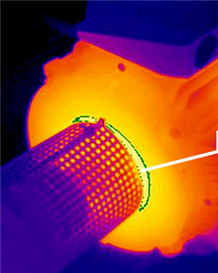

Infrared Inspection is one of the best testing methods, as it is first of all Non Destructive Testing method (NDT).

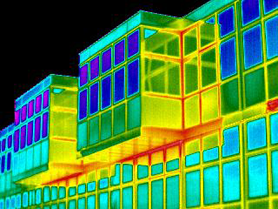

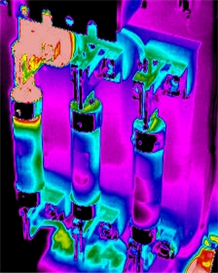

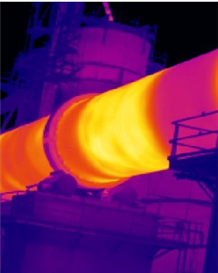

Infrared Inspection can detect potential failure such as loose deteriorated or faulty connections, improper wiring, ground faults, short circuits, faulty devices, overheated cables, overheated circuit breakers, overheated fuses, lose bearings, water leaks, moisture retention, heat loss, and insufficient insulation locations.

Accordingly, recommendations will be given in order to take planned action against these particular scenarios. An Infrared Electrical Inspection is a cost effective means to help avoid costly production and business interruption.

Environmental conditions such as heat, humidity, vibration, spikes, transient energy, etc. cause equipment to become faulty. Faulty assembly leads to poor conductivity and raise the resistance level of electrical components. Interrupted circuits stop current from flowing. Through thermal imaging infrared inspection heat differences can be accurately detected and accordingly interpreted. It is very effective tools for Preventive and Predictive Maintenance.

Excessive heat loss can be caused by faulty equipment or poor ventilation. This heat can be a sign of a problem or problems to come. Visual inspection is limited in finding problems. Electrical testing using Multi-meters is time consuming and difficult to do without system interruption. With the help of Toronto Infrared and our Infrared leading edge equipment and expertise, you can pinpoint and repair electrical problems before the equipment fails. This will ultimately reduce or eliminate your operational downtime and keep your company on a profitable path.

BASELINE INFRARED IMAGING

The best approach to infrared scanning is by scanning all equipment, do the required corrections, and build baseline data.

Baseline data helps determine trending. It can also help adjusting the Predictive and Preventive Maintenance schedule. It can lead to decrease or even increase the maintenance interval for some equipment. All of these can increase productivity, equipment availability and maintenance cost.

Contact Toronto Infrared for Infrared Services today to learn more about our electrical infrared services.

ADVANTAGES

✓ Non-destructive Testing

✓ Very good results without changing the existing installations

✓ Low price for potential high saving

✓ Home air or water leak detection

✓ Find precise location of water leak

✓ Home moisture detection

✓ Leak and moisture detection in flat roofing

✓ Insufficient insulation and voids

✓ Radiant floor inspection

✓ Abnormal heating of mechanical systems

✓ Abnormal heating of electrical components

✓ Abnormal heating of electrical components

✓ Ensure proper functioning of electrical and mechanical equipment

✓ Reduce risk of fire

✓ Find potential electrical problemss

Our Client Are:

Residential

✓ Home Owner

✓ Real Estate Agent

✓ Insurance

✓ Inspector

✓ Appraisal

✓ Contractor

✓ Engineer

✓ Architect

Commercial

✓ Home, office, building, or facility owners / managers

✓ Schools, Hospitals, Offices, Restaurants

✓ Building and home Inspectors

✓ Real Estate Agents

✓ Insurance companies

✓ Appraisal

✓ Contractor

✓ Engineers and engineering firms

✓ Architect

WHY INFRARED?

Reasons To Use Infrared Scanning:

✓ Non-destructive Testing

✓ Very good results without changing the existing installations

✓ Low price for potential high saving

✓ Home air or water leak detection

✓ Find precise location of water leak

✓ Home moisture detection

✓ Leak and moisture detection in flat roofing

✓ Areas of heat loss within homes or buildings

✓ Insufficient insulation and voids

✓ Radiant floor inspection

✓ Abnormal heating of mechanical systems

✓ Abnormal heating of electrical components

✓ Reduce heat and AC cost

✓ Ensure proper functioning of electrical and mechanical equipment

✓ Reduce risk of fire